What are the mold processing equipment?

Precision mold processing equipment determines the quality and performance of the mold to a large extent. We have seven categories of precision processing equipment: CNC equipment, precision Grinding machine equipment, WEDM equipment, EDM equipment, testing equipment, trial production equipment, and other equipment.

General processing equipment list:

- Sheet metal molds: milling machines, surface grinders, wire cutting (fast, medium and slow wire cutting), machining centers, radial drilling machines, bench drills, chamfering machines, tapping machines, hardness testers, etc. Heat treatments are outsourced: such as salt bath furnace, nit riding, carburizing, TD treatment, chromium plating, etc.

- Plastic molds: machining center, precision engraving, electric pulse, wire cutting, grinding machine, drilling machine, wire cutting, chamfering machine, tapping machine, hardness tester, etc. Heat treatment is outsourced: such as salt bath furnace, nitriding, carburizing, TD treatment, chrome plating, etc.

-

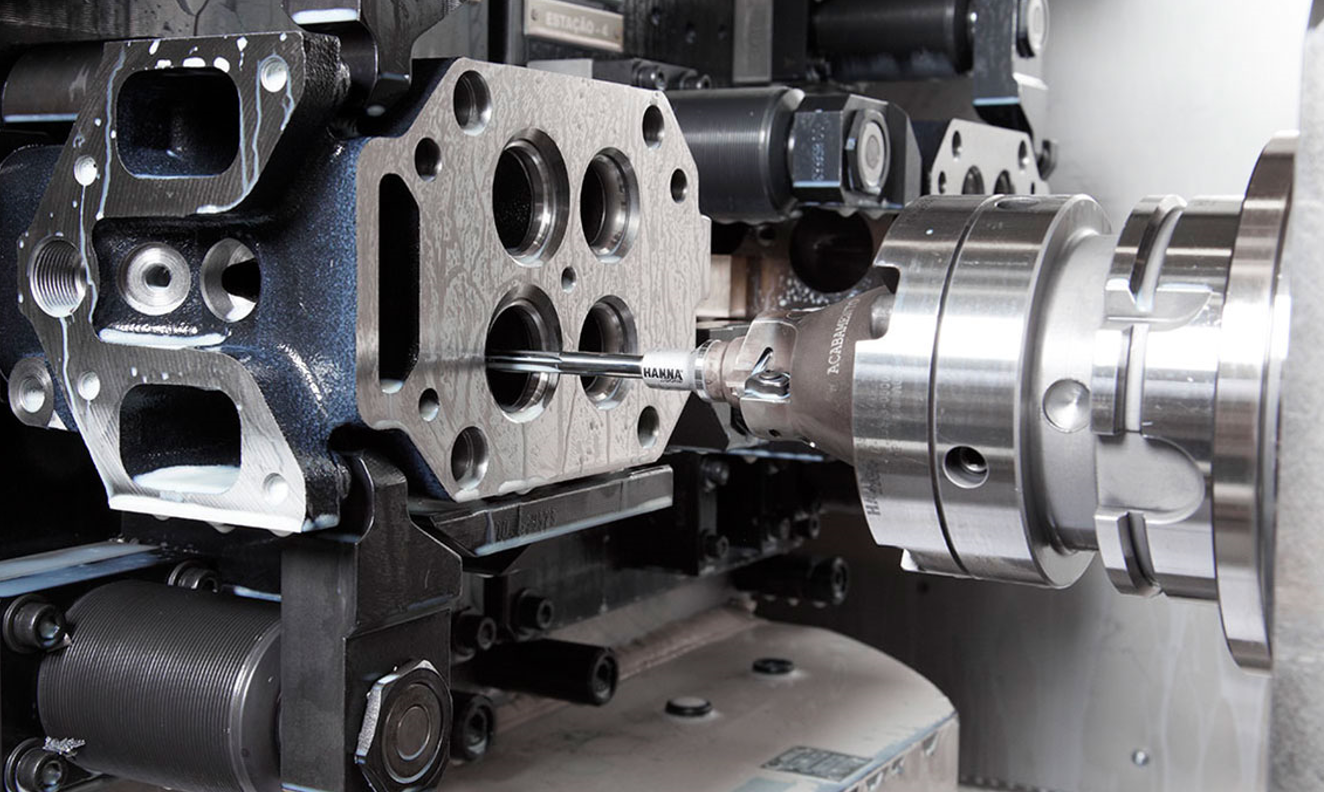

The functions of commonly used processing equipment shown below:

1. The machining center can follow the drawings of the 3D drawing software automatic processing of parts or mold parts. 2. Line cutting can cut relatively small square holes, etc.

3. General lathes are used to process cylindrical parts.

4. Drilling machines and The tapping machine is fixed with screws when the mold accessories are assembled.